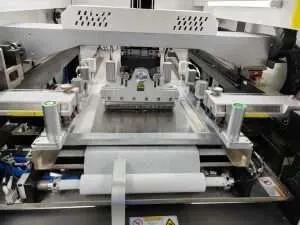

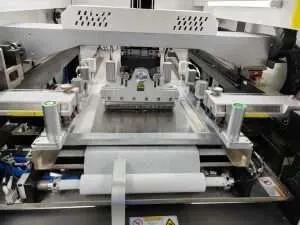

The first step in the PCB assembly process is to apply solder paste to the intended areas to be soldered. This is done by smearing solder paste on the PCB stencil and then using a squeegee to apply it at the designated location on the board.

Obviously, opting for “Made in China” offers a trade-off between quality and price. As a highly promising manufacturer in China, Wells Technology provides an extensive range of assembly services to cater to even the most challenging and demanding projects.

We source electronic components from world-renowned IC manufacturers, such as Qualcomm, TSMC, DigiKey, and Mouser, and we ensure that these components are original and authentic for PCB electronics assembly. In the face of the chaotic component market, we have our own management system and contingency plan. If there is a shortage of materials, our engineers will provide cost-effective alternatives for your review. Additionally, we have a large storage space for components to minimize the risk of global component shortages.

| Item | Capability |

|---|---|

| Max Board Size | 680×500 mm (Smallest: 0.25″x0.25″) |

| Min Component Size | 0.2 – 54 mm (0.084 sq. inch) |

Wave-Solder | — Max. PCB width: 450 mm. — Min. PCB width: not limited. — Component height: Top 120 mm / Bottom 15 mm |

Sweat-Solder | — Metal type: part, whole, inlay, sidestep — Metal material: Copper, Aluminum — Surface Finish: plating Au, plating silver, plating Sn — Air bladder rate: less than 20% |

| Press-fit | — Press range: 0-50 KN — Max. PCB size: 800×600 mm. |

| Quantity | MOQ=0 |

Type of Assembly | — SMT PCB Assembly — Double-Sided SMT PCB Assembly — THT PCB Assembly — Mixed Technology PCB Assembly — Component sequencers, Axial lead inserting, DIP sequence inserting system |

| Solder Type | — Water Soluble Solder Paste — Leaded — Lead-Free |

Components | — Passives down to 0201 size — BGA and VFBGA — Leadless Chip Carrier/CSP — Fine Pitch to 08 Mil BGA — Repair and Reball — Part Removal and Replacement |

| File Formats | — Bill of Materials — Gerber Files — Pick-N-Place File (XYRS) |

| Packaging | — Cut Tape — Tube, Reels — Loose Parts |

PCB Assembly Inspection | — X-RAY — AOI — ICT — Probe Flying — Burn In — Function Test — Temperature Cycling |

PCB Assembly Line | — 7 SMT and THT lines — Same-Day Service to 15-day service — 52 million placements per month — 0.15 sec/chip, 0.7 sec/QFP |

| Advanced Equipment | — Japanese SONY high-speed SMT SI-F130WR Qty: 23 — Japanese SONY multifunctional SMT SI-F209 Qty: 7 — Japanese YAMAHA multifunctional SMT YV100XGP Qty: 7 — DESEN Automatic silk printing machine DSP-1008 Qty: 10 — YoungXin lift slab machines BL-250W-ST Qty: 8 — American Heller 18 zones reflow oven Qty: 4 — America PACEB BGA repair station Qty: 2 — Japanese SONY AOT tester Qty: 4 — 3D-SPI checkout equipment Qty: 2 — ChaoJinDa full-aotumatic ultrasonic cleaning machine Qty: 3 — Japanese X-Ray detector Qty: 1 — YongXing Industrial oven Qty: 3 — Automatic double wave peak welding line Qty: 2 — Automatic belt post-welding production line Qty: 5 — Automatic belt assembly line Qty: 1 — Automatic belt cleaning packaging line Qty: 2 — Computer test maintenance equipment Qty: 15 — Online AOI detection equipment Qty: 4 |

The best PCB assembly service manufacturers should possess the capability to offer customized services tailored to the specific requirements of each customer. This is essential because companies of varying sizes, at different stages, and with distinct needs will have unique demands in terms of projects.

The customer is responsible for procuring all materials, while Wells handles the PCB manufacturing and assembly, as well as PCB testing according to customer needs after the production process is completed. Through past service projects, we have found that some of our customers rely on foreign trade service providers in Hong Kong for procurement, although it is an undisputed fact that their services are good. However, this means that our customers have to bear unnecessary costs, because Wells can provide all the services that these service providers offer.

This solution assumes that the customer already has a stable and high-quality PCB manufacturer. The PCB manufacturer is responsible for manufacturing the bare boards and delivering them to Wells. We then purchase and assemble electronic components according to the requirements of the customer’s documentation.

This type of service can also be referred to as mixed assembly, and it is a fully customizable service option. Customers can combine the different solutions we have mentioned according to their specific needs. This form of service provides maximum flexibility to meet individual customer requirements and achieve successful electronic assembly processes.

If you require factory inspections, we will meet your needs without hesitation. You will observe uniform production lines, qualified technicians, advanced equipment, and more. Below, we have outlined our equipment and production line. If you are interested in our services, please contact us via email, and we will promptly provide you with a quote for cheap PCB assembly.

The first step in the PCB assembly process is to apply solder paste to the intended areas to be soldered. This is done by smearing solder paste on the PCB stencil and then using a squeegee to apply it at the designated location on the board.

Then is the component placement, which is carried out using a pick-and-place robot. These automated devices require precise programming instructions that include predefined X and Y coordinates for each component. The pick-and-place robot then accurately positions the components on the PCB using a vacuum grip.

The success of the assembly project heavily relies on the accuracy of the design documents. To ensure a smooth assembly process, the engineering team at Wells will thoroughly review your design documents prior to commencing the project.

Wells uses a reflow oven with ten temperature zones to complete SMT soldering to form a strong joint.

After reflow soldering, the electronic components may become misaligned due to movement in the holding tray, resulting in open connections or short circuits. Professional manufacturers must identify these errors to reduce the failure rate, for example, Wells will adopt manual inspection, optical inspection and X-ray inspection at this stage.

This involves inserting the pins of the component into the designated PTH holes, which is usually done manually, but Wells offers both AI plug-ins and manual plug-ins, depending on the size of the component and the scale of the project.

For through-hole assembly, it is more beneficial to use wave soldering, but it should be noted that it has difficulty in double-sided PCB assembly.

At this point, the assembly process has come to an end, we will conduct functional tests, electrical tests, etc. on the assembled circuit boards to ensure the success of the assembly and perform the expected functions.

After verifying the accuracy of the PCBA board, it needs to be surface cleaned to remove dirt and stains, and after drying is completed, it is packed with an electrostatic bag and sent to the customer.

Our PCBA services include PCB Fabrication, Component Sourcing, IC Programming, Uploading Firmware, Mechanical Assembly redesigning, and Upgradation. The following is the specific content:

A wide range of assembly services: Including SMT, THT, mixed assembly, flexible, rigid, and rigid-flex.

100% Quality Guarantee: Wells sources all of its parts from reputable suppliers and manufacturers. We thoroughly test and inspect all circuit board components to ensure that they meet the highest quality standards.

Custom Services: We offer customized services that cater to the unique needs of our customers, providing PCBA boards with varying performance parameters to suit different environments. Our team of experts collaborates with you during the process to understand your design requirements and recommend a tailored solution.

Fast turnaround: Our top priority is to deliver PCBAs to electronics manufacturers faster, and this can be easily achieved through our fast turnaround service. Project lead times vary from case to case but typically take a few weeks for standard projects. Assembly lead times may be improved if all components are procured quickly.

PCB is an abbreviation for printed circuit board, and when we refer to it, it usually means bare board.

PCBA board is a rigid body of a PCB with various electronic components and is typically green in color, they consist of a fiberglass substrate, electronic components, conductive traces on copper layers, holes in which the components are fitted, and different layers.

We believe that PCB bare board is unable to function effectively until they are assembled into PCBA board to fulfill their intended purpose in electronics. You can tailor the circuit design according to your specific requirements. Once the printed circuit board assembly is complete, the conductive traces on the PCB facilitate the transmission of digital, high-speed, or analog signals between different points, enabling the desired functionality.

Prior to the advent of pick-and-place robots, the task of component placement was typically performed manually by technicians using tools like tweezers to carefully position each component onto the designated location on the PCB. However, this manual process was time-consuming and labor-intensive, often leading to longer lead times, increased eye strain, and fatigue among technicians.

To address these challenges and enhance the efficiency of PCB assembly and manufacturing, pick-and-place robots were introduced. These automated robotic systems revolutionized the industry by streamlining the component placement process. By utilizing programmed instructions and advanced machine vision systems, pick-and-place robots can accurately and swiftly position components onto the PCB with precision.

A crucial element in the SMT assembly process is the use of commercial reflow ovens. These ovens employ a controlled heating and cooling cycle to securely attach components to the PCB. When selecting a service provider, it is advisable to consider the temperature zones of their equipment.

For hobbyist projects or small-scale assembly, a soldering iron can be utilized for soldering tasks. This handheld tool allows precise application of heat to melt solder and establish electrical connections between components and the PCB.

As long as you have needs, we can provide all testing items, of course, including paid and free. For example, functional testing, flying probe testing, etc. need to be borne by the customer, while for AOI, manual inspection, etc. will be included in the quality control link of Wells.