How Box Build Services Can Benefit You

Reduced Time to Market

Box build assembly enables the integration of multiple components or modules into a cohesive unit, consolidating redundant individual assembly steps in the production process. The use of pre-designed and standardized components further enhances efficiency. These modular units or prefabricated parts reduce the need for custom manufacturing, resulting in improved production efficiency. This is particularly advantageous for businesses with fast turnaround services, as it helps shorten electronics manufacturing cycle times and allows them to gain a larger market share. Electronic manufacturers can leverage this service to reduce the new product development cycle and swiftly gather valuable customer information, gaining a competitive advantage.

Cost Savings

Utilizing PCB box build offers substantial cost reductions for companies in various ways. Firstly, by using standardized components, the need for specialized tooling or custom production processes is minimized. Additionally, the streamlined production process and reduced assembly time result in lower labor costs and increased operational efficiency. Moreover, box assembly services provide scalability, as modular components can be easily replicated and scaled up to production volumes. These advantages are particularly advantageous for companies experiencing growth or dealing with seasonal fluctuations in demand.

Flexibility and Customization

PCBA companies that accept box build orders usually possess a wider range of capabilities to cater to customer flexibility and customization requirements. In PCB manufacturing, they accommodate multiple types of substrates. When it comes to assembly, they offer comprehensive assembly techniques. Moreover, in component sourcing, they provide the ability to combine and configure different modules or assemblies. These advantages enable customers to effectively respond to market and product changes, making project progress and adjustments feasible.

Enhanced Supply Chain Management

Service providers procure pre-designed components from professional and long-term cooperative suppliers to mitigate the impact of component market fluctuations on production progress. Furthermore, the utilization of standardized components and modules enhances the overall quality, reducing the risk of errors or variations during the assembly process. By relying on trusted partners, customers can confidently focus on their core competencies, knowing that their supply and assembly are handled by high-quality components.

Box Build Assembly in China

Required Documents

Assembly Instructions: Guide the manufacturer through each step of box construction, including diagrams, illustrations or photos, etc.;

Bill of Materials: Collation of all necessary components, materials and quantities for the project for procurement by the manufacturer before commencing assembly;

Cut List or Dimensions: Provides precise measurements and dimensions to help determine the walls, bottom and top of the box;

Diagrams or Blueprints: A clear overview of how the different parts fit together helps in understanding the box design, component placement and assembly process.

Safety Guidelines: Outline precautions, safety measures, and best practices to follow during assembly, including information on handling tools, protective gear, and safe use of equipment.

Finishing Instructions: If there are special PCB surface finishes requirements, it needs to be detailed in specific documents, such as painting or dyeing, etc.;

FAQ: During the project, both parties actively discuss and provide common problems and troubleshooting documents to save communication time and speed up the project progress;

Materials and Tools

To complete a box-building assembly, Wells utilizes several essential materials and tools. The necessary materials include box components such as walls, base, and top, which can be crafted from wood, plastic, metal, or composite boards.

Fasteners like screws, nails, or dowels are essential for securely joining the box components together. Additionally, adhesives such as wood glue or epoxy may be used to reinforce joints and provide added strength.

For a polished finish, optional materials like paint, stain, or varnish can enhance the box’s appearance and provide surface protection. As for tools, measuring instruments such as tape measures, rulers, squares, and marking tools are crucial for accurate measurements.

Cutting tools such as saws or jigsaws enable precise shaping of the box components according to your desired size. Fastening tools like screwdrivers, drills, or nailers aid in the assembly process, while clamps ensure the components remain securely in place.

Sanding tools like sandpaper or a sanding block are necessary for smoothing rough edges and surfaces. If a finishing coat is desired, brushes, rollers, or sprayers may be required. We take into consideration your specific requirements, carefully plan your project, and gather all the necessary materials and tools before commencing the box assembly.

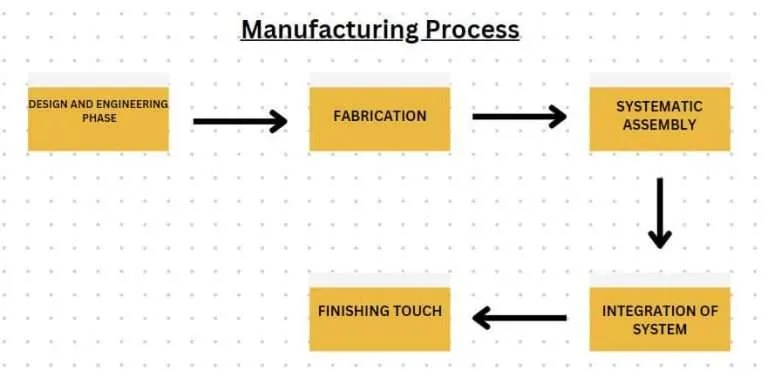

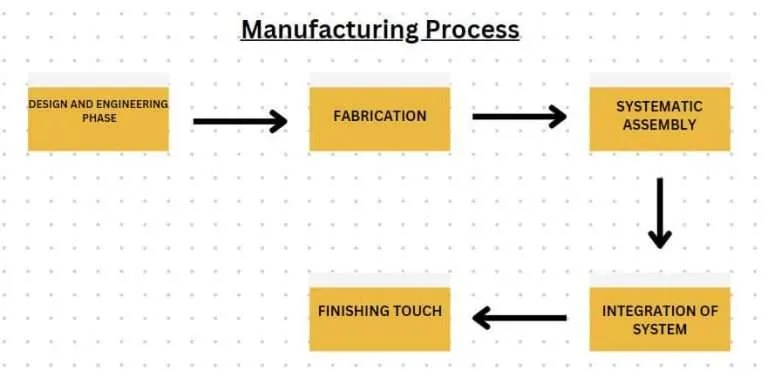

Box Build Assembly Process

High-quality PCB Box Build Assembly Service