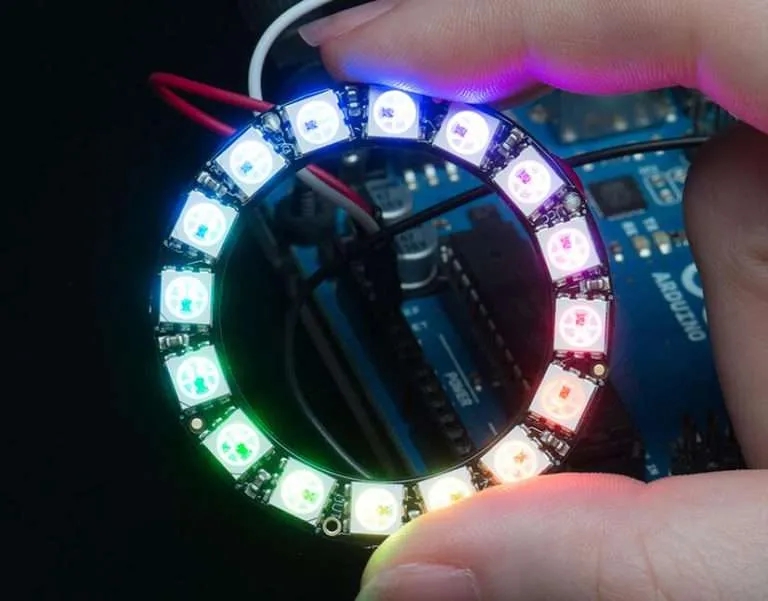

The rapid advancements in lighting technology have brought about a significant revolution in the field of illumination. Among the various options available, light-emitting diodes (LEDs) have gained immense popularity due to their remarkable energy efficiency, durability, and versatility. An essential component that lies at the core of every high-efficiency LED light is the LED printed circuit board (PCB). Wells acknowledges the pivotal role of LED PCB in driving growth and has forged long-term collaborations with renowned LED lighting engineers worldwide. Our primary objective is to support and facilitate the evolution and development of our customers through our comprehensive manufacturing and assembly services.

Best LED PCB Manufacturer-Wells

From its inception, Wells has focused on the consumer electronics and LED industries, making them the core of our business. As our operations expanded, we successfully ventured into the industry and the Internet of Things sector. Our commitment to professionalism remains unwavering, whether it pertains to low-end or high-end PCB. Leveraging this expertise, we have established ourselves as the leading LED PCB/PCBA manufacturer in Shenzhen, China. Our competitive edge lies in our ability to deliver manufacturing services of the highest quality, ensuring both efficiency and speed.

Service Capability

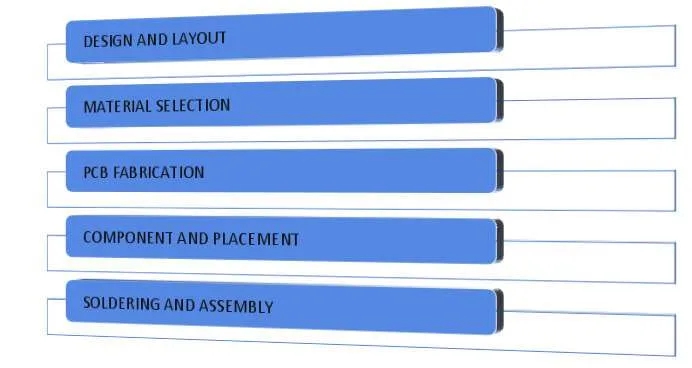

LED Bare Board Manufacturing + Assembly Service

Efficiently Meeting the Demand for LED Components

Rapid Prototyping + Expedited Service

Support for Design Assistance + Enhancements

Comprehensive Array of Testing Methods(AOI, FAI, FPT, Functional Testing and more)

Fabrication Capacity

Direct Ownership of Factory, Eliminating Brokers

Significant Production Capacity to Meet Demands

No MOQ Requirement

Industry’s Most Competitive Prices

Industry-Recognized Certifications for Application in Medical, Automotive, and Other Fields

Aluminum-based LED, flexible LED, SMD-mounted LED, etc.