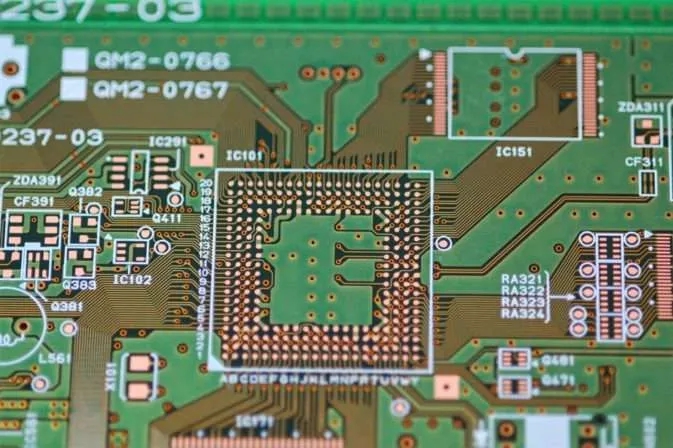

EMS stands for Electronics Manufacturing Services, also known as Electronics Contract Manufacturing (ECM), which is a rapidly growing industry. It refers to companies that offer contract manufacturing services for electronic components and equipment. As manufacturers for electronic product brand owners, these companies provide a comprehensive range of services, including manufacturing, procurement, part design, and logistics. EMS offers a wide range of services in the electronic components field, making them the preferred service provider for companies in this field.

Compared to traditional OEM or ODM services that only provide product design and contract production, electronic manufacturing service companies offer knowledge and management services, such as material management, logistics transportation, and even product maintenance services.

Premium EMS Electronic Service

Outsourcing non-core businesses to professional EMS companies is an increasingly popular trend in the electronics manufacturing industry. Choosing Wells as your service provider is a wise decision that will positively impact your company’s operations. With over 10 years of experience in PCBA contract manufacturing, we offer high-quality PCB Assembly Services tailored to meet the diverse needs of our customers. Our services include turnkey, partial turnkey, and consignment, among others. It’s important to note that each contract manufacturing company specializes in different areas, and taking the time to understand the company’s detailed information and capabilities is crucial in ensuring the quality of printed circuits.

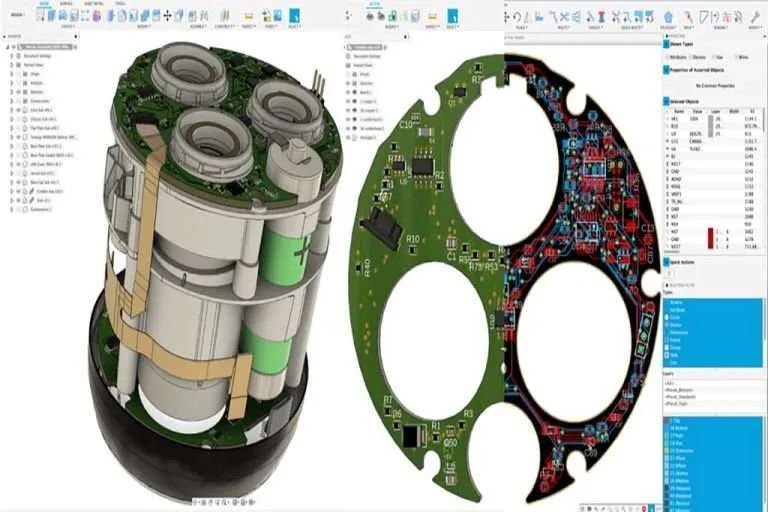

CAD Modeling & Mass Production

3D CAD modeling plays a crucial role in achieving high volume PCB assembly. At Wells, we use CAD software to create precise and detailed digital models of our customers’ products. These 3D models are then used to verify the design and check the real shell of the electronic products through printing methods. This helps to identify any necessary debugging before production, significantly reducing errors and speeding up the process.

After the model is complete, CNC machines are employed to create molds for the final product. These molds are used to produce multiple copies of the product using techniques such as injection molding, casting, or stamping.

Various Housing Material

As a professional EMS PCBA manufacturer, Wells is proficient in using various types of housing materials to meet different customer requirements. We offer a wide range of customization services for plastic, soft materials, metal, and wooden shells, such as ABS, silicone, steel, and aluminum materials, depending on the project’s needs. This means that we have strong resource mobilization capabilities and can provide customers with high-quality products, even in the face of component shortages during large-scale production.

If you are looking for cheap contract PCB assembly opportunities, Wells is the right choice. We have the patience to find affordable alternatives for customers, saving them time searching for reliable housing suppliers, Wells will help with taking care of the details discussion.

System Integration Services

System integration services are a core aspect of contract PCB assembly. This service involves combining different subsystems or components of an electronic system to function as a whole. It includes assembling power modules, motherboards, heat sinks (coolers or fans), memory modules, displays, I/O interface connectors, motors, and other accessories.

During the manufacturing process, specialized components are required such as ribbon cables, stranded or solid wires, RF coaxial connectors, cable clamps, connectors, terminals, ground metal bodies, cooler components, and silicone on cable ties. These components are crucial for achieving optimal performance and ensuring the reliability of the electronic system.

Mechanical Assembly

Mechanical assembly is a crucial aspect of EMS circuit board manufacturing and requires skilled workers and specialized assembly plants. It involves the process of combining electronic and mechanical components to create a finished product. This process may include tasks such as drilling screw holes, riveting, tightening nuts and bolts, adding washers and mechanical locks, and assembling the core functional parts into the final enclosure.

Assembling a simple product with no subassemblies is more efficient than assembling a product with multiple subassemblies. Generally, the more subassemblies a product has, the more man-hours are required for the assembly process. This can pose a challenge for some PCB assembly contract manufacturers, but Wells has extensive experience in this field and advanced equipment, which serves as evidence of our capabilities.

Programming/Setup

After the hardware assembly is completed, an Electronics Manufacturing Service Provider can assist with the initial factory programming or configuration of the product. This process involves programming microcontrollers, sensors, and other electronic components to enable the product’s functionality. The programming content includes firmware or driver installation, date or time setting, manufacturing code, operating system configuration, and BIOS update, among other things.

Wells has a team of experienced engineers and technicians who are proficient in IC programming and the configuration of various electronic components. We use the latest software tools to program and test our products, giving our customers confidence in their products before shipment.

Labeling and Signs

Our team pays attention to every aspect of the PCB assembly process, including the small details that can often make a big difference in the final product. When we receive a quotation request, we carefully review the BOM and Gerber files, as well as any specific requirements or details provided by the product designer. This attention to detail extends to labeling and signage, and we can assist with placing or printing logos or labels on the product body as needed. Common Label types includes:

Product specification and parameter info

Usage specification and mandatory identification of user region

Manufacturer info of the product

Functional Testing

Most OEM manufacturers find it difficult to customize test fixtures to meet customer needs, but Wells can solve these problems through its electronic contract manufacturing services. We can help customers build custom test stations to avoid the delivery of defective products, which also relieves the cost-increasing problems of local delivery and commissioning.

In our laboratory, we are equipped with common functional testing equipment, including switch machine testing, signal output analysis, resistance testing, keyboard testing frequency, burn-in testing, or any other tests required by customers. Additionally, for some special products, we also provide customized PCB assembly inspection services, and these special tools and testing equipment will communicate and coordinate with customers.

Package

Wells offers customized package box design and manufacturing as part of our PCB contract manufacturing services to meet the specific needs of our clients. Our packaging service follows a standard operating procedure (SOP) that ensures the product is packaged with the correct components, warranty card, user manual, assembly and disassembly instructions, and any other required materials. This guarantees that users have a complete understanding of how to use and operate the product, as well as any necessary precautions. Our packaging service is just one of the many manufacturing services we offer to our valuable clients.

Storage and Shipment

Before delivery, our products are carefully packed and stored in our well-managed warehouses by our experienced warehouse officer and factory guard. They maintain appropriate temperature and humidity levels and ensure the shelves are clean for safe storage. This is a crucial aspect of our EMS electronic service.

At Wells, we work with a stable and competitive delivery company to ship our products worldwide. If clients prefer to use another shipping company, we can assist them in arranging custom clearance documents to ensure timely delivery of their products. This enables us to provide quick turnaround times and meet our clients’ delivery needs.

After-sales services and maintenance

As a reliable PCB manufacturer, we understand the importance of providing comprehensive post-sales support to our clients. That’s why we offer a range of repair, maintenance, and calibration services that help our clients ensure their products operate at peak performance for extended periods.

Our post-sales services are designed to help our clients save time and money by eliminating the need to hire and train skilled technicians to carry out routine maintenance tasks. With our team of experienced professionals, we can quickly identify and resolve any issues that may arise, ensuring that our clients’ products are always functioning optimally. We use state-of-the-art equipment and technology to diagnose and repair issues promptly, minimizing downtime and ensuring our clients’ products remain operational.