In the past, much of the work in factories was done by hand. This mode of production not only reduced industry efficiency but also caused physical and mental exhaustion for workers. Fortunately, those days are long gone, and now we invest heavily in machinery and equipment for industry. These high-end machines can accurately complete various complex processes in a short amount of time.

To enable engineers to produce factory equipment that meets various performance requirements, the demands for industrial PCB manufacturing are increasingly stringent. Many people think that a circuit board is just a circuit board, and that there is no difference in how it runs programs and operates in different environments. However, this is clearly wrong.

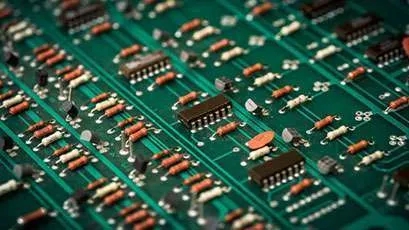

An industrial PCBA, also known as an industrial control board, is a circuit board designed to withstand shock, vibration, extreme temperatures, humidity, and dust in industrial equipment. This PCBA is used to perform many operations in the industrial control industry. It is designed to configure the circuit of a project in a compact manner, which allows current to flow accurately in the required path and enhances product operation. These boards are also critical components of industrial control projects and equipment, helping to measure and configure numerous parameters of the assembly line, and obtain accurate physical quantities.

| Maximum number of layers | 36 |

| Board thickness | 0.25″ |

| Maximum Panel Size | 23.62″x39.37″ |

| Impedance toleranc | -/+ 5% |

| Minimal Laser Drilling | 0.002″ |

| Minimal Mechanical Drilling | 0.0059″ |

| Min trace and space | 0.0015″ |

| Drilling process | Blind Buried Vias |

Industrial SIL: Stands for Safety Integrity Level, and measures the safety performance of Safety Instrumented Systems (SIS).

IEC 61511: Is a process industry-specific standard that provides guidance for the specification, design, installation, operation, and maintenance of safety instrumented systems (SIS) in the process industry.

IPC-6012: Specifies the qualification and performance requirements for rigid printed circuit boards, including base material, conductor configuration, hole requirements, surface and internal conductors, and marking.

IPC-2221: Defines the design requirements for printed circuit boards, including board layout, trace width and spacing, via dimensions, and other design aspects.

UL 94: Tests the flammability of plastic materials used in the construction of electronic equipment. PCBs that meet this standard are made of flame-retardant materials.

RoHS: Is a directive that restricts the use of six hazardous substances in the manufacture of electronic and electrical equipment, and industrial PCBs must comply with this directive.

If you are considering outsourcing your PCBA projects, you must look for a manufacturer that can provide quality services at affordable prices. It is essential to choose a supplier that is well-known and has experience in the field of PCBA industry, like Wells PCBA. Along with various relevant certifications and references, our company has a team of highly skilled engineers and employees who are proficient in handling micro-operations, as well as state-of-the-art instruments.

The complexity of consumer electronics PCBA cannot be compared to that of industrial control machinery. Therefore, we recommend that customers opt for turnkey solutions for their complex projects. With a turnkey supplier, you can rely on them to handle everything from the prototyping stage of the industrial control board to final production, testing, and delivery. These manufacturers also have a complete feedback system that can provide you with details of your projects from start to endpoint. Ensure that the project creation and management process is the easy and straight word and that the manufacturer has details responses related to any query.

Having extensive manufacturing experience is crucial when selecting a PCB manufacturer. It is also beneficial for the manufacturer to have completed similar projects in the past, in addition to a strong background in PCBA manufacturing. Wells is a company that meets these requirements. With over 10 years of experience in PCBA processing and expertise in industrial control board projects, including power supply units, robotics, electronic switch gears, industrial drives and inverters, electronic test and measurement equipment, energy control systems, and industrial smart meters, our team is well-equipped to handle various industrial projects.

Industrial PCBs can often be expensive due to various factors, such as design complexity, number of layers, and materials used. To mitigate the cost overhead, it may be sensible to choose Chinese manufacturers who can often produce PCBs with lower labor and material costs. However, it is important to note that while cost is a crucial factor to consider, it should not come at the expense of quality. It is crucial to find a manufacturer with the capabilities to produce industrial PCBs that are both cost-effective and high-quality.

The issue of poor quality industrial control circuit boards is absolutely intolerable. When these boards are used in industrial equipment, any errors can result in significant losses for the customer, including costs associated with downtime. As such, PCBA manufacturers must implement strict quality management practices, which goes beyond simple PCB inspection and involves many other factors.

The placement of components on the board layout is a critical factor to consider when designing industrial control PCB boards. Improper component placement can affect the reliability and performance of the final product. During PCB board design, special care must be taken to ensure that components are installed on the board with a minimum of 100 mils space between the edges of the board and the mounted components. This ensures that the dimensions of the board and mounted holes are consistent.

| Industrial PCBA | Attributes | Commercial PCBA |

| For a specific application rather than a purpose | Design | For general use |

| Rugged to withstand harsh environments | Material | More cost-effective |

| Industrial control system | Application | Consumer Electronics |

| Stricter testing and quality control measures | Test | Relatively simple, fewer projects |

| Expensive | Cost: | Cheap |

| Class 2 or Class 3 | IPC 6011 | Class1 or Class 2 |

| Construct the PCB symmetrically around the central axis in the z direction. | Stackup Balance | Regular |

| Balance between Heavy Copper Weight and Normal Copper Weight | Copper Consistency | Regular |

| Consistent temperature distribution is necessary for uniform flow of solder during PCBA. | Thermal Consistency | Regular |