Whether it’s manufacturing or assembly, speed is our focal point in prototype projects. This accelerates project progress, giving you a greater edge in the competitive market. To achieve this, you must utilize manufacturers like Wells, offering rapid PCB prototyping services.

A prototype plays a crucial role in the development process, allowing businesses to test and evaluate their designs before proceeding to mass production. At Wells, we offer comprehensive prototyping services that encompass two key aspects: PCB prototype manufacturing and PCB prototype assembly.

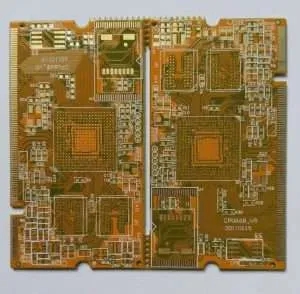

Our PCB bare board prototype service aims to verify and validate the functionality, layout, and signal integrity of the circuit design, ensuring it meets the specified requirements. Through meticulous testing and evaluation, we help identify potential issues and optimize the design for manufacturability and cost-effectiveness.

Additionally, our assembled prototype service goes beyond individual components, focusing on the functionality and performance of the entire system. By meticulously assembling and testing the prototypes, we enable businesses to identify and resolve any issues early on, reducing project costs and facilitating faster time-to-market.

Best Prototyping Services

Reliable Prototype Manufacturer

Established in 2008 in Shenzhen, China, Wells is a leading provider of PCBA solutions for global high-end electronics manufacturers. With our extensive expertise and vast resources, we are dedicated to delivering exceptional quality services to our valued clientele.

When it comes to electronic prototyping projects, we fully comprehend the critical requirements of our customers, namely, uncompromising quality and accelerated turnaround time. To meet these demands, we consistently invest in state-of-the-art equipment, ensuring swift project completion. Moreover, we go beyond expectations by offering additional services such as design review, PCB testing, and comprehensive quality control measures to guarantee top-notch results.

Thanks to our unwavering commitment to professionalism, many of our clients have transitioned from prototype development to large-scale production with us. We eagerly await the opportunity to impress you with our utmost dedication and provide you with a personalized quotation.

Prototyping Project Details

Wells operates with multiple departments to deliver comprehensive PCBA solutions including the procurement, design and production department. To ensure a seamless production process, we conduct an NPI (New Product Introduction) meeting where each team member involved in the process will thoroughly understand the project details. During the prototype PCB assembly process, we prioritise the following crucial aspects:

Component Selection: We meticulously procure components from trusted suppliers, guaranteeing functionality and reliability. Our commitment extends to providing cost-effective alternatives as part of our value-added service.

Soldering Quality: Prior to commencing prototype PCBA, we conduct solderability testing to ensure secure component-to-board connections and reliable electrical performance.

Testing and Validation: Wells conducts comprehensive testing and validation of the PCBA prototypes to ensure optimal functionality after production.

Documentation: From PCB board prototyping to PCBA prototyping, we maintain meticulous documentation to enable seamless replication and scalability for mass production.